High Melt-Strength Polypropylene Technologies

Polypropylene (PP) is a thermoplastic linear hydrocarbon polymer produced from its monomer, propylene, using a chain-growth polymerization process. PP is a polyolefin that is partially crystalline and non-polar. It has highly linear chains with a relatively narrow molecular weight distribution (MWD). PP’s properties such as high tensile strength, high modulus, high stiffness, chemical resistance, excellent heat resistance, and low cost are benefits. However, the consequences of high linear structure are low melt strength and poor melt extensibility, making PP difficult to be used in extensional flow-dominated processes, such as extrusion foaming, thermoforming, extrusion coating, and blow molding. High melt-strength PP (HMS PP) was developed to make PP more competitive with other materials such as polystyrene and polyethylene in these applications. Techniques to make HMS PP include broadening the MWD, increasing molecular weight, and/or creating long-chain branched structures using irradiation of PP in an inert environment, introduction of long chain branches using peroxides, reactive extrusion of grafted polypropylene as crosslinking, or in-situ reactor production.

Market Drivers and Major Players in the HMS PP Market

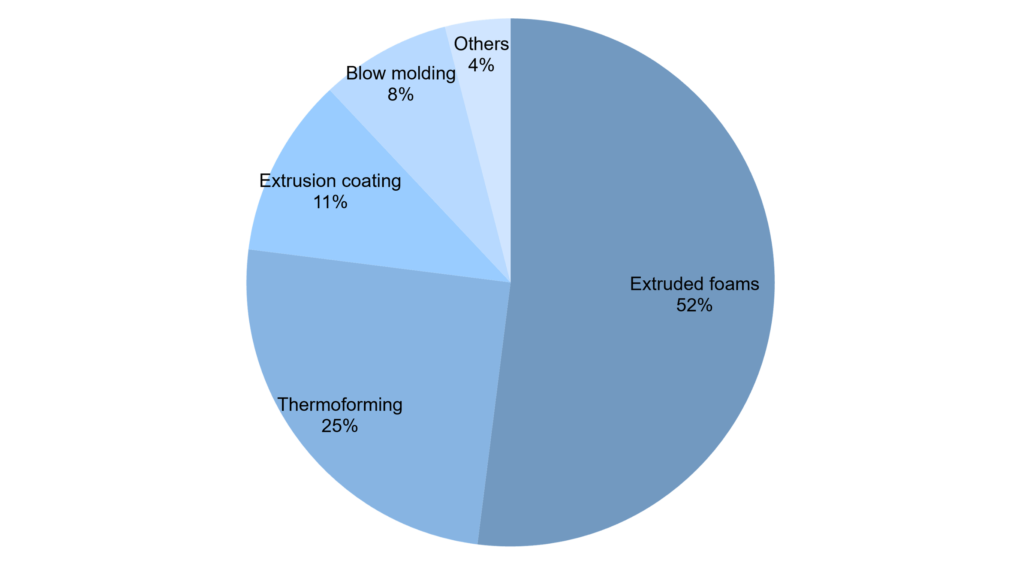

HMS PP producers include Borealis, Japan Polypropylene (JPP), and Braskem. The main applications of HMS PP include extruded foams, thermoforming, extrusion coating, and blow molding. Some smaller applications include blown films, extrusion profiles, and others. Applications such as automotive interiors and exteriors, thermoformed foam food packaging, insulation, flooring underlayment, and others use HMS PP foam. Historically, North America and Europe have been the largest consumers of HMS PP. These regions continue to witness steady growth, while the rise in consumption in regions such as China and Rest of Asia will be the growth driver for the overall demand of HMS PP. Exhibit below shows the North American demand for high-melt strength PP by application.

Exhibit 1. North American demand for high-melt strength PP by application in 2014 in percentage

Polypropylene Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis of current market dynamics and overview of industry growth drivers, with global and regional demand analysis forecast over the next five, 10, and 20 years. The report is based on thorough analysis of the industry through detailed interviews with all the major players including PP producers and end-users. The geographic focus of the market assessment will be regions segmented into North America, Latin (Central and South) America, Europe, Japan, China, Rest of Asia, and Rest of World. The report will benefit present and future PP market participants; PP producers and compounders; and individual end-users, entrepreneurs, and organizations attempting to understand the complex market and capture future growth.

Table of Contents

Click here to view the table of contents.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.