Polyolefin Catalyst Technologies

Polyolefins produced using catalysts in low-pressure reactors include linear polyethylene resins (LLDPE, MDPE, and HDPE), and polypropylene (PP). Conventional catalysts used in polyolefin manufacturing processes include precipitated or supported Ziegler-Natta (ZN) catalysts, or chrome-based catalysts on silica. In the 1990s, single-site metallocene catalysts with a transition metal, such as titanium or zirconium, sandwiched between one or more cyclopentadienyl rings, came into use for making polyolefins. More recently, advanced ZN catalysts have been developed. One polyolefin--low-density PE (LDPE)--uses a different process that does not use these catalysts but may involve organic peroxide initiators. Catalysts are one crucial part of the process, and the type of reactor (eg, gas-phase reactor, slurry-loop reactor) is another. The reactor and the catalyst create polymers with specific characteristics. ADI CMR has specialized reports on the global markets for the polyolefin product families, including metallocene-catalyzed elastomers and plastomers, MDPE/HDPE, and PP.

Market Drivers in the Polyolefin Catalyst Market

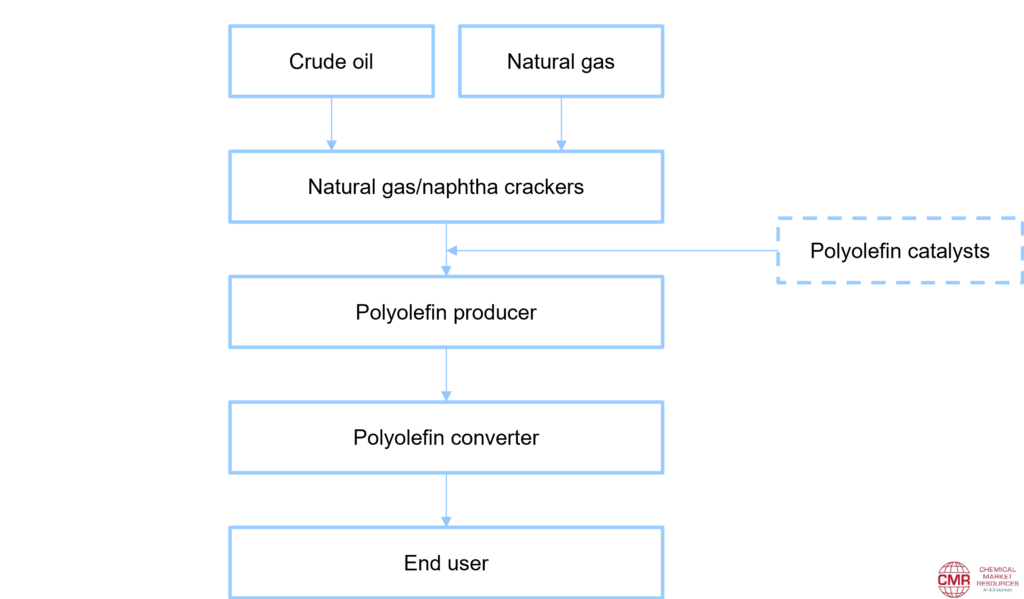

Catalysts for low-pressure polyolefin processes were initially supplied by the technology licensors, but as patents have expired, third-party producers have entered the market. For example, with the expiration of key metallocene patents in 2011, the technology held by a few is becoming more widespread via licensing and cross-licensing catalyst agreements. Each catalyst supplier (inventor or third-party) has a specific catalyst portfolio. The expansion of the polyolefin industry overall, with new capacity being built in the US as well as other areas, is driving demand for catalysts. Catalyst selection determines the properties of the polymer; producers choose a catalyst based on their target market and the properties that the end-use application requires. The exhibit below shows the value chain at a high-level. Catalyst selection determines the properties of the polymer; producers choose a catalyst based on their target market and the properties that the end-use application requires.

Exhibit 1. Polyolefins value chain

Polyolefin Catalyst Market Assessment

ADI Chemical Market Resources (ADI CMR) has conducted a strategic analysis that covers all major developments in the industry including changing market dynamics, technology trends, evolving industry structure and strategic alliances, and the current and expected competitive landscape. Market forecasts are presented by region and application. This study will assess the relative position of each catalyst supplier in this niche, but dynamic and high-margin market. Another goal of this study is to review the catalyst needs per region and per process technology. The report is based on thorough analysis of the industry through a wide range of methods, including published information, patent searches, ADI CMR proprietary projects, and interviews with catalyst suppliers and resin producers. The report will particularly benefit polyolefin producers, and catalyst suppliers, as well as individual end-users, entrepreneurs, and organizations attempting to understand these complex issues and capture future growth in the marketplace.

Table of Contents

Click here to view the table of contents for this report.

Prospectus

Please fill this form and check your email for a link to download the prospectus. For a custom report on a topic of your choice or an updated version of an existing report, please contact us at +1 (281) 506-8234 or info@adi-cmr.com.